Laser cutting technology has transformed various industries, providing efficient and precise material processing methods. However, ensuring the safety of laser cutter operators is crucial due to the potential hazards involved.

To create a secure working environment, it is vital to design protective uniforms tailored specifically for these operators. This article explores the importance of such uniforms in reducing risks and promoting a safety culture.

We will discuss key considerations, including material selection, ergonomic design principles, and compliance with safety standards. Additionally, we will explore the integration of advanced technologies like heat-resistant fabrics and protective coatings to improve the well-being and productivity of laser cutter operators.

By implementing these safety solutions, organizations can prioritize the welfare of their operators and foster a sense of belonging in the workplace.

Key Takeaways

- Laser cutting is widely used in industries such as manufacturing, automotive, aerospace, and healthcare.

- Laser cutter operators face risks such as eye injuries, burns, hearing damage, and exposure to hazardous fumes and particles.

- Safety hazards associated with laser cutting applications include severe eye injuries, fires and explosions, and respiratory issues.

- Protective uniforms for laser cutter operators should be made from flame-resistant materials, provide full body coverage, be comfortable and breathable, and include essential safety features.

Understanding the Importance of Laser Cutting Applications

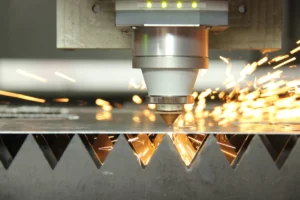

Laser cutting applications play a crucial role in various industries, offering precise and efficient solutions for cutting and engraving a wide range of materials. This technology utilizes a high-powered laser beam to vaporize or melt the material, resulting in a clean and accurate cut.

The applications of laser cutting are vast and diverse, spanning industries such as manufacturing, automotive, aerospace, and even healthcare. In manufacturing, laser cutting is used to create intricate patterns and shapes in metal, plastic, and wood. In the automotive industry, it helps to produce precise components for vehicles.

Aerospace companies rely on laser cutting to fabricate lightweight and durable parts for aircraft. Additionally, laser cutting has found its place in the medical field, enabling the production of intricate surgical instruments and implants.

With its precision and versatility, laser cutting has become an indispensable tool in modern industries.

Common Challenges Faced by Laser Cutter Operators

Laser cutter operators often face a range of common challenges in their daily work, requiring careful attention to safety measures and specialized protective equipment.

One of the main challenges is the risk of eye injuries due to the intense laser beam. Operators must wear appropriate safety goggles or face shields to protect their eyes from potential harm.

Another challenge is the potential for burns or skin damage caused by direct contact with the laser or hot materials. To address this, operators should wear flame-resistant clothing and gloves.

Additionally, the noise generated by laser cutting machines can pose a challenge, leading to hearing damage. Operators should wear earmuffs or earplugs to protect their hearing.

Lastly, the emission of hazardous fumes and particles during the cutting process can be a health risk. Operators must work in well-ventilated areas and wear respiratory masks to avoid inhalation of harmful substances.

Safety Hazards Associated With Laser Cutting Applications

When considering laser cutting applications, it is important to be aware of the safety hazards associated with this technology. Laser cutting involves the use of powerful laser beams to precisely cut materials, and if not properly managed, it can pose significant risks to operators.

Here are three safety hazards associated with laser cutting applications:

- Eye damage: The intense laser beams used in cutting can cause severe eye injuries if operators do not wear appropriate protective eyewear. Direct exposure to the laser beam can result in permanent vision loss or even blindness.

- Fire hazards: Laser cutting generates a significant amount of heat, which can ignite flammable materials. Without proper precautions, such as fire-resistant workspaces and adequate ventilation, laser cutting system can lead to fires and explosions.

- Inhalation of toxic fumes: When certain materials, such as plastics or metals, are cut using lasers, they release hazardous fumes and particles. Operators must wear respiratory protection to prevent the inhalation of these toxic substances, which can cause respiratory issues and long-term health problems.

Key Considerations for Designing Protective Uniforms

To ensure the utmost safety for laser cutter operators, it is essential to carefully consider various factors when designing protective uniforms.

These key considerations play a crucial role in providing operators with the necessary protection against the potential hazards associated with laser cutting applications.

One important factor to consider is the material used for the uniforms. It should be flame-resistant and able to withstand high temperatures and sparks.

Additionally, the uniforms should provide full coverage to protect the operator’s body from any potential laser beam exposure.

The design should also allow for ease of movement and comfort, ensuring that the operator can perform their tasks efficiently without any hindrance.

Furthermore, the uniforms should be easily washable and maintainable to ensure cleanliness and hygiene.

Essential Features of Protective Uniforms for Laser Cutter Operators

One crucial aspect to consider when designing protective uniforms for laser cutter operators is incorporating essential features that prioritize safety and comfort. These features not only ensure the protection of the operator but also enhance their overall work experience.

Here are three essential features that should be included in protective uniforms for laser cutter operators:

- Flame-resistant materials: Laser cutting involves high temperatures and sparks, making it crucial for the uniforms to be made from flame-resistant materials. This helps to minimize the risk of burns and injuries.

- Full body coverage: Laser beams can cause harm to exposed skin, so protective uniforms should provide full body coverage. This includes long sleeves, pants, and closed-toe shoes to prevent any potential accidents.

- Breathable and lightweight fabric: While safety is paramount, it is also important for laser cutter operators to feel comfortable while working. Using breathable and lightweight fabric in the uniforms allows for better airflow and reduces the risk of overheating or discomfort.

Best Practices for Implementing Safety Solutions in Laser Cutting Applications

To ensure safe working conditions in laser cutting applications, it is essential to implement best practices for implementing safety solutions. These best practices include conducting a thorough risk assessment to identify potential hazards and determine appropriate safety measures.

It is important to provide comprehensive training to laser cutter operators on safe operating procedures, including proper use of personal protective equipment (PPE) and emergency protocols. Regular maintenance and inspection of laser cutting equipment is crucial to identify any potential safety issues and address them promptly.

Implementing engineering controls, such as installing barriers or enclosures around the laser cutting area, can also help minimize the risk of accidents. Additionally, establishing clear communication channels and promoting a culture of safety awareness among all employees can further enhance the effectiveness of safety solutions in laser cutting process.

Frequently Asked Questions

What Are Some Common Challenges Faced by Laser Cutter Operators?

Some common challenges faced by laser cutter operators include the risk of eye damage from laser radiation, potential exposure to harmful fumes and gases, and the need to wear protective clothing to prevent burns and injuries.

What Are the Safety Hazards Associated With Laser Cutting Applications?

Safety hazards associated with laser cutting applications include exposure to high-intensity laser beams, risk of eye damage, inhalation of toxic fumes, and potential for burns or fires. Proper protective measures, such as designing protective uniforms, are essential to mitigate these risks.

What Are the Key Considerations for Designing Protective Uniforms for Laser Cutter Operators?

When designing protective uniforms for laser cutter operators, key considerations include fire resistance, heat insulation, and protection against hazardous materials and sparks. Comfort, breathability, and ease of movement are also important factors to ensure operator safety and productivity.

What Are Some Essential Features of Protective Uniforms for Laser Cutter Operators?

Some essential features of protective uniforms for laser cutter operators include flame-resistant materials, full coverage of the body, and reflective strips for visibility. These features help ensure the safety and well-being of operators while operating laser cutting machines.

What Are Some Best Practices for Implementing Safety Solutions in Laser Cutting Applications?

Some best practices for implementing safety solutions in laser cutting applications include providing comprehensive training for operators, ensuring proper ventilation and extraction systems, implementing strict safety protocols, and designing protective uniforms that offer adequate protection from laser radiation and sparks.

Conclusion

In conclusion, designing protective uniforms specifically tailored for laser cutter operators is crucial for ensuring their personal safety and mitigating risks in the workplace.

By considering factors such as appropriate materials, ergonomic design principles, and compliance with safety standards, manufacturers can develop innovative solutions that provide effective protection without compromising comfort or functionality.

Integrating advanced technologies, such as heat-resistant fabrics and protective coatings, further enhances the overall well-being and productivity of laser cutter operators, fostering a culture of safety in laser cutting applications.

You May Also Like: